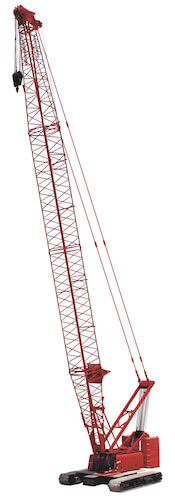

The 999 boasts a number of the most recent proprietary technologies developed by the manufacturer, including the proven Electronically Processed Independent Controls (EPIC), delivering precise load control. Closed-loop hydraulics on the Manitowoc-999 allow for variable speed operation of the swing, load hoist and boom hoist, independent of one another. Easy, compact mobility means this 275-US ton model can be transported anywhere in the US.

Featured Special Attachments:

- Fixed Jib & Luffing Jib

Featured Special Attachments:

- Fixed Jib & Luffing Jib

* significant capacity increase when utilizing heavy lift attachments

Top BHL Projects

Top BHL Projects

BHL Serves a Variety of Industries

Combined Cycle Power Plant

Cocoa Beach, FL

- Project: Combined Cycle Power Plant

- Location: Cocoa Beach, FL

- Equipment: Boom Configuration: 257′ Main Boom – SDBW

- Scope: For this project, our crane company was able to utilize our Buckner HeavyLift set HRSG, Steam Turbine and other associated equipment to construct the Combined Cycle Power Plant in Cocoa Beach, FL.

Arthur Ashe Stadium

New York, NY

- Project: Retractable Roof Lift

- Location: New York, NY

- Equipment: Buckner HeavyLift Cranes’ Liebherr LR 11000/P 1300 , two Liebherr 1600/2

- Scope: Preliminary planning and layout determined the proper configuration to ensure the sufficient capacity for all the lifts. As one of the most advanced crane companies in the industry, Buckner constructed a steel, retractable roof structure over the largest tennis stadium in the world.

Stennis Space Center

St. Louis, MS

- Project: A-3 Test Stand

- Location: Bay St. Louis, MS

- Equipment: Liebherr LR 1600/2 SDWBW – 197′ Main Boom, 118′ Luffing Jib

- Heaviest Pick: 415,000 lbs

- Scope: This project consisted of our crane company setting tanks and vessels for the A-3 Test Stand at Stennis Space Center in St. Louis, MS.